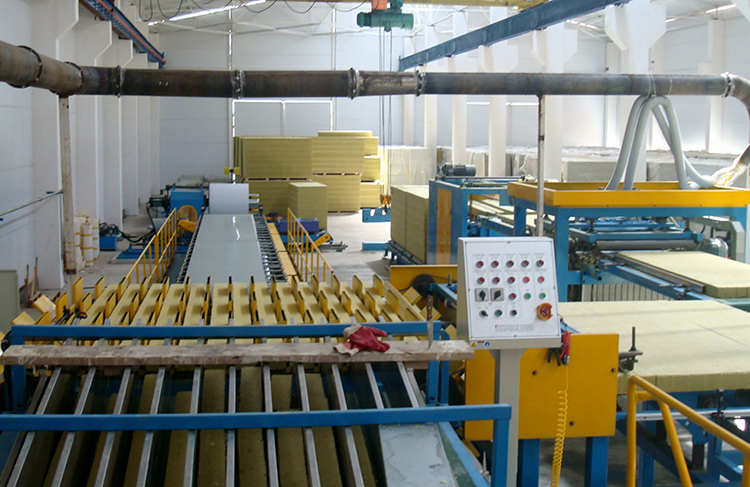

Mineral wool sandwich panel line

Composition

| Step 1. |

Decoiling system |

| Step 2. |

Roll forming system |

| Step 3. |

Mineral wool board feeding system |

| Step 4. |

Adhesive(glue) system |

| Step 5. |

Side PU injection system |

| Step 6. |

Laminating system |

| Step 7. |

Cutting system |

| Step 8. |

Cooling system |

| Step 9. |

Stacking system |

| Step 10. |

Wrapping system |

Our mineral wool and rock wool sandwich panel production line is already recognized its value by major sandwich panel producing companies at domestic and foreign with various technical researches and a high level services, we will keep trying for development in accordance with customer’s needs for the high quality sandwich panels.

Specification for mineral wool sandwich panel line

| Kind of products |

Interior wall, Exterior wall(Secret fix), Corrugated roof, Metal and more |

| Density of core material |

Standard 40K~150K |

| Production speed |

Average 4~16m/min |

| Annual capacity |

About 800,000㎡ |

| Necessary dimension |

Approximately W15m x L100m x H7m |

| Required electric power |

About 200kw |

| Required air pressure |

Minimum 6~7bar |